-

Posts

7,075 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by davey_83

-

Ello n welkom Looks nice, stick around

-

Subscribed fella Can't get enough product reviews and detailing goodness, plus RHD Z bonus - keep em coming

-

Glad you getting it sorted and never feel embarrassed to ask about the condition of brakes and tyres (pictures if need be) as for these cars it's a big cost to put right. Suspension compression arms on the front are common for wearing and don't often show up on an MOT, yet can be noisy over bumpy ground. Which set of tyres did you go for, as Formula 1 garages do some good deals on sets of rubber.

-

Hold fast youngen

-

Yes I have an addiction From the last CarChem haul I actually didn't get an interior cleaner or wax it wet, so what's a boy to do. https://www.autofinesse.com/en

-

Looks AMAZING!!

-

New 370Z Nismo Owner in Surrey

davey_83 replied to Loadmaster's topic in Introductions & Welcome Messages

Elli n welkom She looks beautiful -

No worries, you'll find the mention of 20/25mm relates to hub spacers not lowering springs

-

Cheers pal, these are Apex springs and the spats are Nismo replicas. Springs sit perfect when coupled with 19's possibly a bit too low with 18's

-

This worked on my 350z, as it's the same era car

-

Perfect, can't tell it was ever there. I had one half way along the door on the crease and another ding just above.

-

Had Dent Devils out to work a bit of magic on the Z. Wasn't a bad one, but once you see it, you can't unsee it. Don't know how I got a dent, she doesn't go anywhere

-

The Nismo logo on the V1 alloys isn't put on, they're embossed

-

I'll never forget the moment when news went out of this achievement, fantastic stuff.

-

I'll take it chap PM'd

-

Clean sexy hardware

-

Great work, looks really nice craftsmanship. Subscribed

-

Cheers pal I've seen a fair few who fit the UR W brace and leave the kidney covers off, I thought no way I've given the w brace a go over in ACF50, so we'll see how well that holds up.

-

-

Cheers lads. I know minimal surface rust underneath thankfully and now all treated and protected. Even the w brace front bolts still had their factory zinc coating. Someone went to town on the underseal soon after purchase, R&R of the centre brace shows a pneumatic finish right up inside the transmission tunnel.

-

Taking one for the team

-

Jammie gits!!!!

-

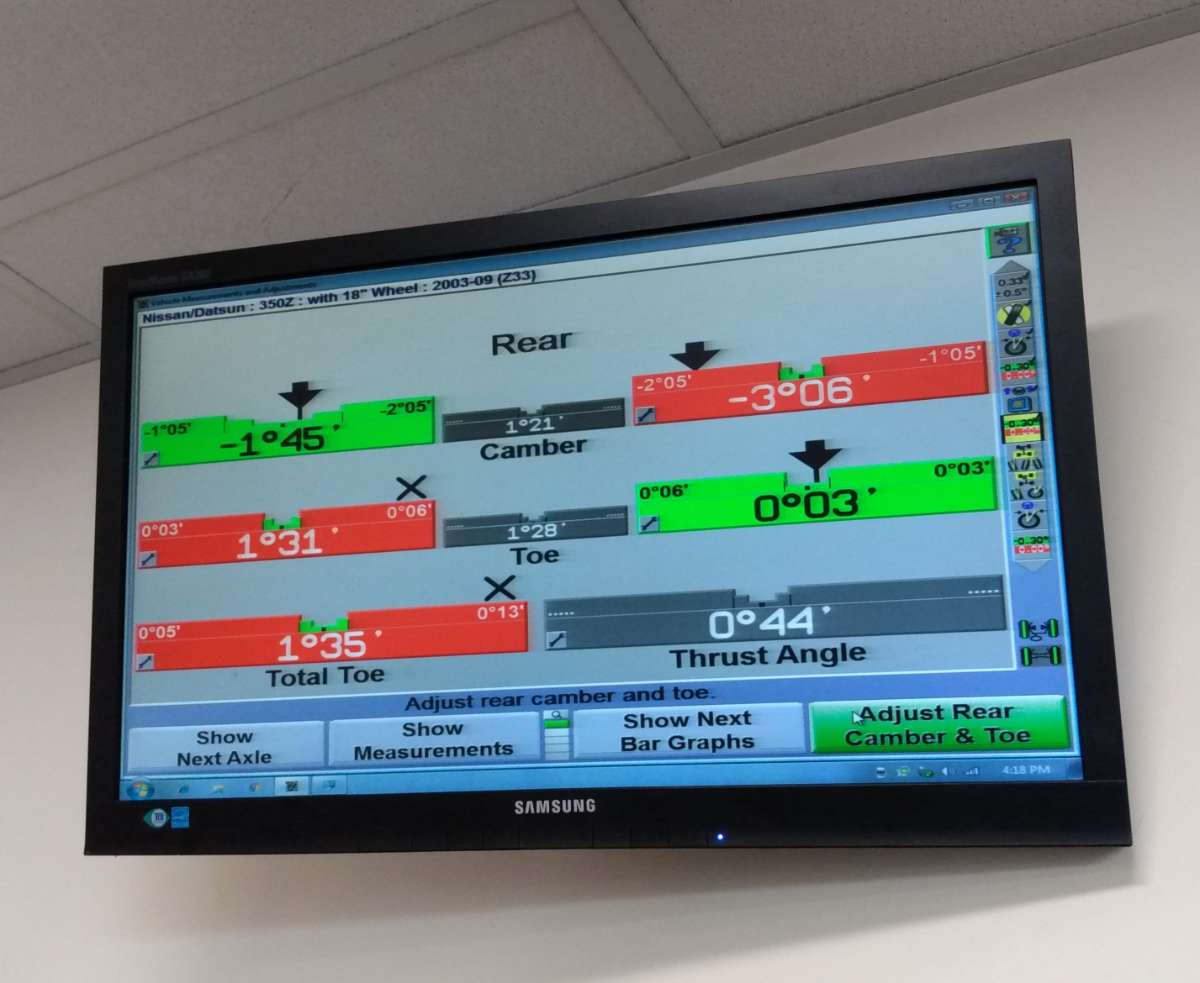

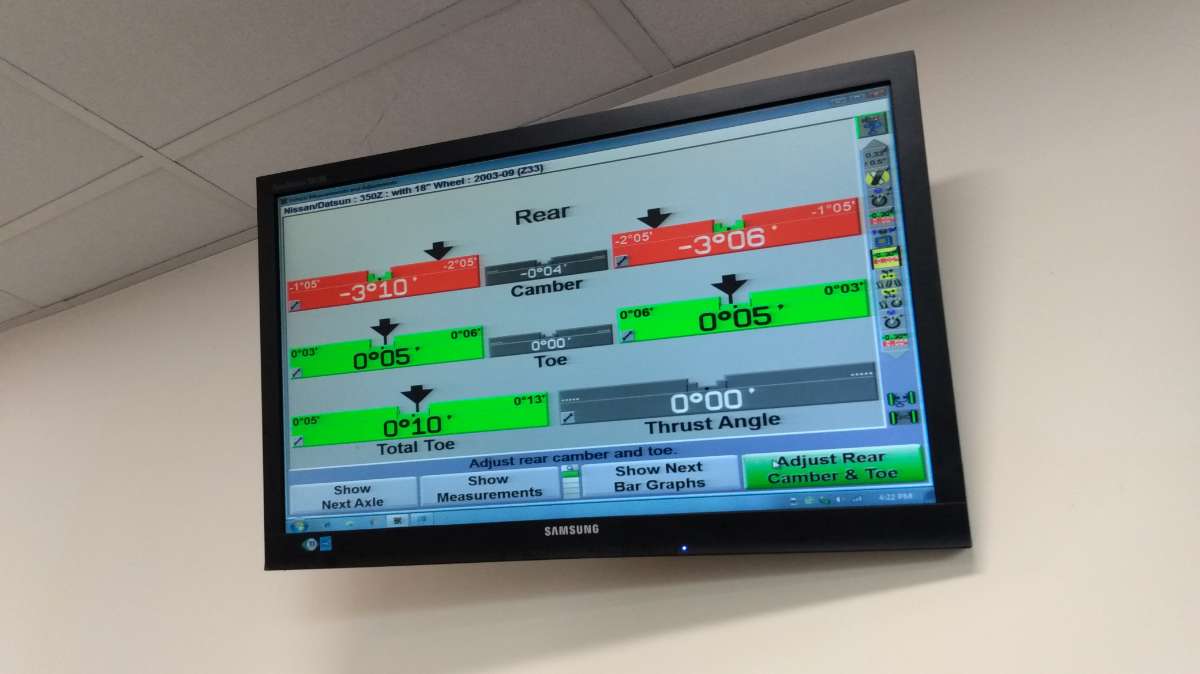

Few more lockdown jobs tackled recently on the Z. Rear ARB SuperPro poly bushes, Ultra Racing W brace and Tarmac Sportz rear camber arms. With a bits and pieces removed it made sense to also sort out a few rust issues, mainly kidneys mounts, sills and rear box sections around the rear silencer - all prone to rust sadly. In all honesty my OE W brace wasn't in a bad state at all, as from the get go I rust treated and painted to prolong its life. Being lowered -30mm, rear camber arms were of course on the to do list. Even by eye you can tell the standard rubber bush opening is slightly larger than the new poly bush, meaning it's worn which is to be expected for 15yrs and 88k of service. Thankfully every nut and bolt came off without a flight, even the rear camber bolts and rear w brace boots which are known for snapping. Threads in the new adjustable camber arms greased prior to fitting. So I can pretend to be doing a decent job. Anti roll bar brackets, cleaned, treated and protected. W brace hardware cleaned, greased and ready to go. Kidney mount covers cleaned and dressed. Rust wire brushed, carb cleaned left to dry then treated. The 350z doesn't come with factory underseal, so this is either dealer or aftermarket but I can say it's very good. You can see it's integrity compared to the part covered by the factory w brace. Left for 24hrs to do its thing and the next day began to underseal. No fun doing this on axle stands but such is the way. All back together and looking loads better. I've eye balled a few turn of adjustment on the arms to reduce negative camber. Parts aluminium weren't touched as not a concern in terms of corrosion. Now this is where the fun began!! Went to go for a drive as you do and the car felt awful!! To the point of thinking something is desperately wrong. Jacked her up, checked lug nuts and every other nut and bolt that I had touched - all tight. Checking all around the ARB and differential for anything that appeared out of place and came across a thin washer for one of the ear mounts for the diff out of place. Thought that's strange and managed to wiggle this piece out. The other side has this same washer type piece but when in the right place the bolt would go through the hole so should never come out of place. This must have worked it was loose from the car being repeatedly jacked up from the diff. So now because this plate was removed *by hand, the bolt was now loose compared to the other side. Remembered reading on here that Whiteline had revised their instructions to show the thicker bush needs to go at the top. Ok, another job to do. Consulted with a couple local Z heroes Martin and Nick on the best way to do this. Left it for a while as the weather turned pants and feeling disheartened after all my earlier efforts. Straight forward to swap the bushes out on the drive and better the issue occuring now rather than miles from home, on a b road in North Wales with no phone signal. So differential bushed sorted and now mounted tight, how does it drive? Better but still really off!! Ok, before going any further, let's get the wheel alignment sorted. that'll teach me Without adjustable toe arms, it became a juggling act aiming for correct rear toe without excessive camber. Less camber resulted in greater toe in. Fronts needed minimal adjusting but now she drives great again, phew.

-

Same, nothing received as yet and ordered early doors. Running low on a couple items, so naturally holding out to see what I get.