-

Posts

1,355 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Store

Everything posted by andybp

-

I try to please Chris I would have loved to have a go on scrapheap challenge and also completely unrelated Ninja Warrior (Japanese not British)

-

I can't wait either hopefully it won't go through the very very long development process of my rear mount turbo but really I'm not that fussed as long as I'm having fun

-

? it's the same car same suspension Nope, the suspension is different between the two cars. Stiffer on the rear on the 86, stiffer on the front on the BRZ. The difference is far more noticeable than you might think, too. Without knowing the mechanics of it, the BRZ is harder to provoke into oversteer than the GT86. Even in the wet it feels less boisterous. Well I consider myself told but then I've only driven the 86 tried to persuade my mrs to buy one but she bought the 2.0 tfsi tt instead unreliable crap

-

? it's the same car same suspension

-

I think nearly all the fixings are M6 not sure what length though

-

The 350z ITB kits you're talking about are the OBX ones and with the import duty they come in at a fair bit more but as much as they are a Individual Throttle body Kit you cant just bolt them on and turn the key this is purely the mechanical components no throttle position sensors no way to open the throttles either cable conversion or Drive by wire no tuning solution either I'm guessing that a working setup would cost £2k+ at this point in time my homemade setup is set to cost me maybe £300 and yes the modified 350 throttle body is because I want to keep the drive by wire At the end of the day the cost wasn't the big decider between buying and diy I just enjoy doing it oh and this is my finished modified throttle body just need to sand and paint the fibreglass over the new connector

-

got a bit more done today, since I will be using two external throttle position sensors I need to re-route the cables from where they connect to the internal ones this is it stripped down showing the four contacts +5v 0v tps1 and tps2 new connector wired in just need to do some fibreglassing now also nearly forgot the mechanical side of it is finished minus the seal to protect the bearing because I don't have it yet

-

So this is progress believe it or not this is my machined down 350z throttle body and the machined piece of ally about to welded to it so I have somewhere to fit the second bearing to support the output shaft and here it is all welded together and machined to take the support bearing I'm hoping to get this pretty much finished tomorrow

-

already decided I'm going to machine 0ne out of ally so I can give myself as much clearance as possible as it's going to be underneath the trumpet. so maybe with a filler at 45 deg pointing towards the front but will just make a temporary one for now so I can get it fitted

-

Great work as always but the only problem with making it pretty by grinding off the welds is that you weaken it as long as you got proper penetration it won't be a problem though (yes I know I said penetration )

-

yea could have been worse I've got to delete that map today. In my defence of the sentence I started typing and the missus shouted up the stairs "are you coming to watch this film" so had to rush.

-

So I had my MOT today and I was prepared I put in three progressively leaner maps into the ECU as I had a problem with high hydrocarbons last year I'm guessing either my High flow cats are just not up to it or maybe O2 sensors but sticking a lean map into the ECU did the job only had to go to the second map to get it under 200 so I'll worry about the reason for it another day then he tests the brakes, all good then when he tries to reverse it off the rollers to put it up on the ramps it stalls then it's back firing and sounds awful so really doesn't look good he cant even get it off the rollers so I take a look and notice the problem straight away he's accidentally hit the switch to change maps with his elbow and selected the map I used when I had the rear mount turbo setup the problem with the UTEC ECU I have is it can 5 maps but only 1 parameters file so the maps need to be either all MAF or all speed density so my ECU was trying to run the engine really really rich but never mind all sorted now and I can get on with my individual throttle bodies now that's out of the way for another year.

-

Quality over quantity that's what I tell the wife

-

Who knows but it's amusing

-

No no airbox (at the moment anyway) and I want to use quite long Air horns/trumpets so it's really in the way or was before I bought this new rocker cover

-

Minor update hopefully this is the solution to my clearance problem with the filler on the rocker cover Not sure exactly what this cover is from an Elgrande I believe I will have to make a filler cap for it and modify the breather at the back but that's minor in the big scheme of things

-

Epic or a complete failure only time will tell

-

Got some good weather today so got my machined down lower plenum on the Z to check the clearances which turned out to good and bad The thing I thought might be a problem was the fuel rails but that was fine plenty of room the thing I never even thought of, the oil filler was not so good Shortening and angling the ally tube the throttle bodies will be fitted into helps matters and I would have to do this anyway but doesn't solve the problem After much searching I've ordered another rocker cover which should solve this particular problem which I'm sure is only the first of many problems I'll come across but if it was too easy where would be the fun in that.

-

born in 1940 alien was 1979

-

I like them all but Aliens and Alien resurrection the most

-

You're 39 I thought you were younger also don't be a wuss they're not real you know.

-

throttle bodies arrived early so managed to get all six throttle bodies bored out also the guy I got them from threw in a freebie and I also now have the map sensor to go with them

-

got two of the throttle bodies bored out today takes about 30 minutes for each one but I haven't had much time today these are the ones I've done also for comparison next to a standard one the replacement ones for the one I damaged should show up next week but I'm on 24hr standby all next week so weather dependent if I get anymore done also I checked the resistance of the throttle position sensors compared to the standard nissan one, the nissan one appears to half of the ones on the new throttle bodies shouldn't really matter as it should still give a 0-5v output not the end of the world if it doesn't work just have to find some suitable ones.

-

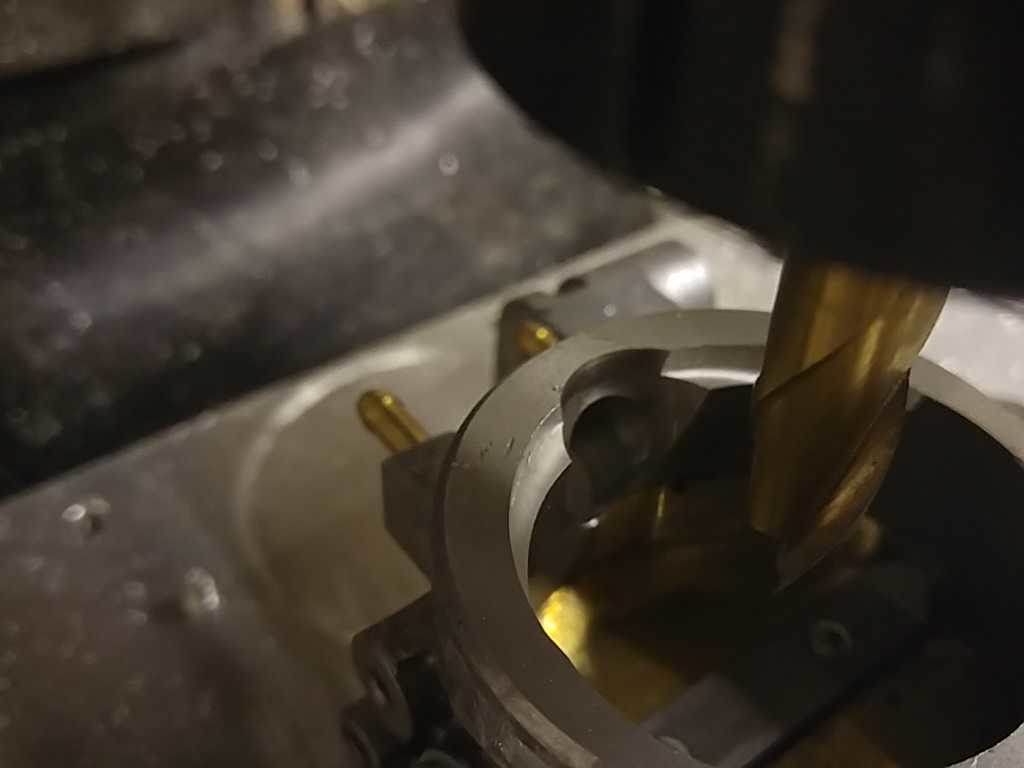

thought I'd do what I can while waiting for some decent weather so I thought I would remove the tapered area of the throttle bodies where the injector usually comes in as in this application it's just a restriction as seen here so after lots of measuring and a bit of programming, my milling machine is merrily removing the restriction for me but the only problem with computer controlled equipment like my CNC milling machine is the computer because sometimes they lock up for no reason so it did breaking an expensive carbide end mill and one throttle body but never mind just have to buy more. Computer seems happy again now so put in a new end mill and the next throttle body and got started should get these finished tomorrow (if the missus let's me)

-

Not much of an update second set of throttle bodies have arrived along with the rubber o rings I will be needing and the longer bolts I will need to bolt the throttle bodies together once i have made up the spacers also I have started to machine the standard 350z throttle body I will be using to operate my ITB's This projects going to be a bit slow until I can get some reasonable weather so I can remove my inlet plenum and do some measuring.